In Oil & Gas facilities, the safety and reliability of production processes do not depend solely on the quality of infrastructure or operational protocols, but also on the ability to continuously monitor the environment in which people and machinery operate. The presence of flammable, toxic, or asphyxiating gases represents a real and ongoing risk, especially in highly complex contexts such as refineries, offshore platforms, processing plants, and storage facilities. Gas detection in the Oil & Gas sector is therefore an essential element to ensure operational continuity, prevent major incidents, and comply with the most stringent safety regulations.

Oil & Gas: why monitor gases

Integrating gas detection systems in Oil & Gas facilities means:

Promptly detecting the presence of hazardous gases, even at low concentrations;

Protecting operators and maintenance personnel from potentially lethal exposure;

Reducing the risk of major incidents, fires, and explosions;

Preventing unplanned plant shutdowns and costly production downtime;

Supporting compliance with safety and environmental regulations;

Ensuring long-term process continuity and operational reliability.

Oil & Gas: main sources of risk

In the Oil & Gas sector, gas leaks can occur at multiple points in the process:

Extraction units and wellheads;

Treatment and refining plants;

Transfer lines and pipelines;

Storage tanks and loading/unloading areas;

Compressors, valves, and flanges;

Offshore areas exposed to harsh environmental conditions.

Which gases should be monitored in Oil & Gas facilities?

Among the most common and hazardous gases to be detected in the Oil & Gas sector are:

Flammable gases (methane, propane, butane): risk of fires and explosions;

Hydrogen sulfide (H₂S): highly toxic, even at low concentrations;

Carbon monoxide (CO): colorless and odorless gas, extremely dangerous;

Volatile hydrocarbons (VOCs): associated with health and environmental risks;

Oxygen (O₂): monitored to prevent dangerous oxygen-deficient or oxygen-enriched conditions.

Correctly identifying the gases to be monitored is the first step in designing an effective and reliable gas detection system.

Gas detection technologies in the Oil & Gas sector

High operational criticality requires robust, accurate, and certified technologies. The most commonly used solutions include:

Catalytic sensors: ideal for detecting flammable gases in ATEX areas;

Infrared (IR) sensors: stable and reliable for flammable gases and hydrocarbons, even in harsh environments;

Electrochemical sensors: specific for toxic gases such as H₂S and CO, offering high sensitivity.

Integrating gas detection systems with supervision and control platforms (SCADA, DCS, or BMS) enables real-time plant monitoring, immediate alarm management, and rapid activation of safety procedures.

Technological advancements are making these systems increasingly flexible, reliable, and suitable for complex industrial scenarios.

Safety regulations in Oil & Gas facilities

Oil & Gas facilities must comply with stringent regulations that ensure high levels of operational safety, including:

ATEX Directives for equipment installed in potentially explosive atmospheres;

IECEx certifications for international applications;

Guidelines for the protection of workers’ health and safety.

Beyond ensuring legal compliance, these regulations serve as a benchmark for industry best practices. Implementing certified gas detection solutions reduces the risk of non-compliance, strengthens the trust of customers and stakeholders, and helps consolidate corporate reputation over the long term.

The benefits of an integrated gas detection system

Adopting a gas detection system specifically designed for the Oil & Gas sector delivers tangible and measurable benefits:

Enhanced protection of personnel and critical assets;

Reduced risk of major incidents and environmental damage;

Improved operational continuity and production optimization;

Better control of operating costs through rapid and targeted interventions;

Alignment with international safety standards.

Discover our products

Sensitron gas detectors are suitable for use in any application:

SMART S-MS

Designed to withstand marine conditions, it is used to detect flammable gases and refrigerants. ATEX and MED certified.

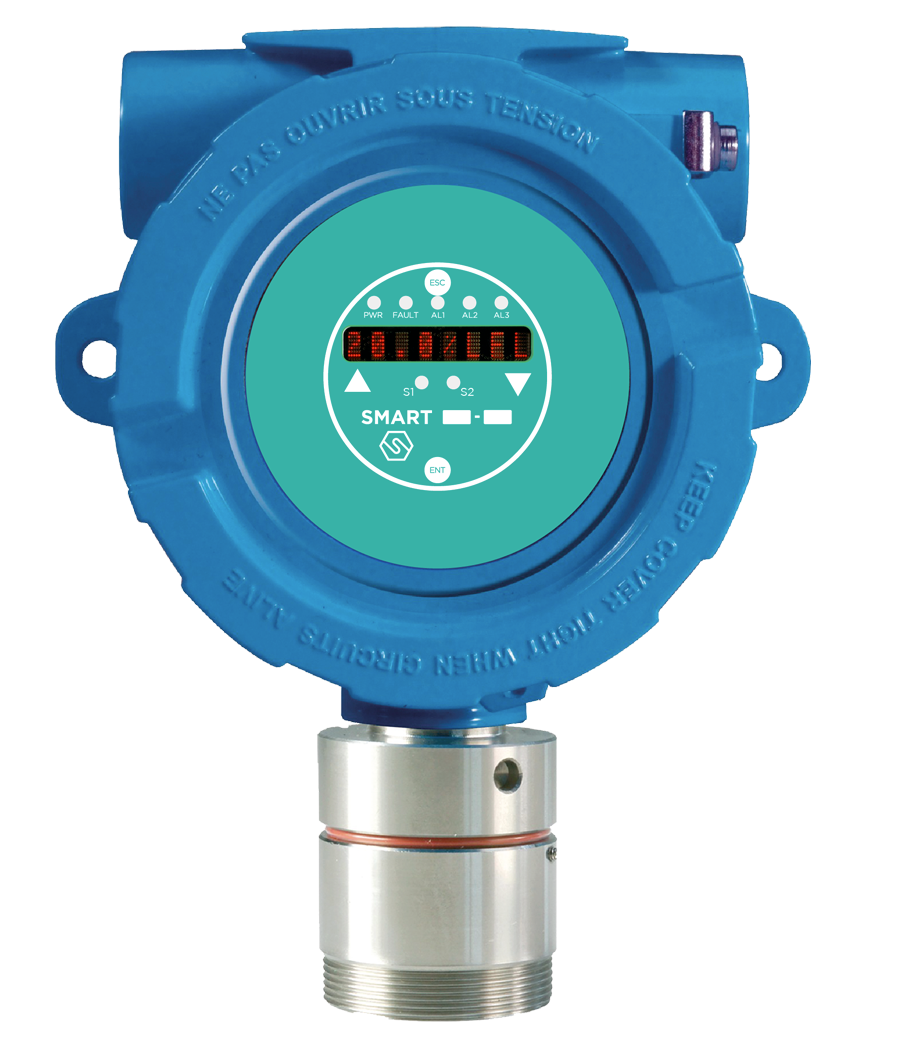

SMART S-SS

Designed to meet the most stringent industry standards, it is used in hazardous areas for the detection of flammable and toxic gases, CO2, VOCs, and refrigerants. ATEX certified, it can be equipped with a HART modem.

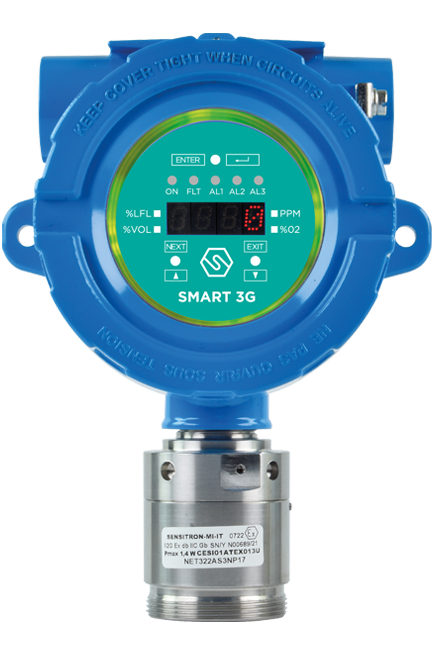

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.ATEX, IECEx and SIL2/3 certified.

Our certifications

In hazardous environments where strict safety standards must be met, it is important to use certified products that comply with regulations. Discover our certifications:

ATEX

The Directive sets out the requirements and assessment of equipment intended for use in potentially explosive atmospheres.

IECEx

The IECEx system is an international certification system. It is developed by the International Electrotechnical Commission.

SIL

The Safety Integrity Level (SIL) is the ability to reduce the assessed risk by ensuring the reliability of safety systems.

Explore in virtual reality

Within the Sensitron metaverse, you can explore application scenarios reconstructed in virtual reality. Find out more about who we are and what we do, walk through a production area and learn more about the dangers associated with gas.

Follow us on Linkedin