The energy sector is one of the most sensitive areas in terms of industrial safety and environmental impact. From power generation to hydrocarbon refining, via hydrogen and biomethane, the management and detection of hazardous gases is a key element in protecting people, plants and the environment.

Energy sector and gas hazards

In the energy sector, potential emissions of flammable gases (such as methane, hydrogen or propane) or toxic gases (such as carbon monoxide and hydrogen sulphide) can result in serious accidents, explosions or damage to the health of operators. Greenhouse gases, such as methane and carbon dioxide, are also monitored for their climate impact, in line with environmental sustainability goals.

Effective gas detection makes it possible to prevent accidents, intervene promptly in the event of leaks and ensure the operational continuity of plants.

Critical gas detection applications

Gas detection solutions find application in numerous segments of the energy industry:

- Natural gas production and storage plants

- Refineries and thermal power plants

- Hydrogen (H₂) and power-to-gas sites

- Biogas and biomass plants

Decompression, compression and distribution cabins

In all these contexts, early detection of dangerous leaks is essential to avoid serious consequences.

Energy industry: what are the right technologies?

Sensitron designs and manufactures gas detectors that meet the most advanced technological and regulatory requirements. Solutions offered include:

- Catalytic sensors for flammable gases

- Electrochemical sensors for toxic gases

- Infrared detectors for critical environments

- ATEX-certified devices for hazardous areas

The adoption of smart detection technologies enables integration into centralised and automatic supervision systems for environmental conditions.

Why rely on Sensitron for the energy industry

The increasing use of alternative energy sources and the spread of environmentally friendly gases (such as hydrogen) make gas detection a key element in meeting the challenges of the energy transition.

Sensitron’s solutions support companies and public authorities in achieving decarbonisation goals, promoting a safer and more sustainable future.

Discover our produtcs

Sensitron gas detectors are suitable for use in any application:

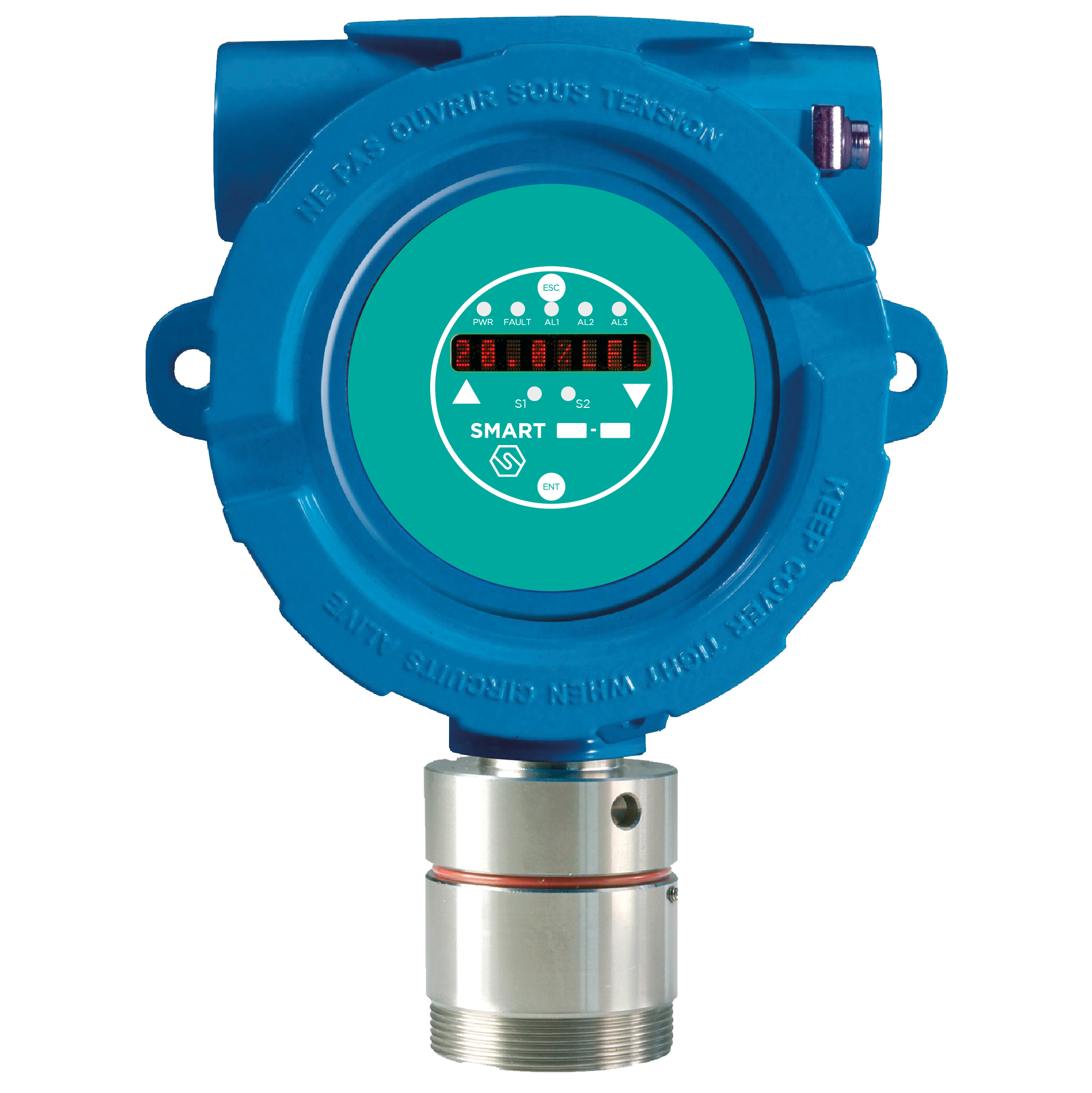

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.ATEX, IECEx and SIL2/3 certified.

SMART S SS

ATEX certified for Zone 1, SIL2 Hardware and SIL3 Software, optional Hart Modem and possibility to have it with stainless steel housing.

MULTISCAN++ S1/S2

Designed to meet the widest market demand for flexibility, they allow the management of up to 264 detectors. ATEX and SIL certified.

Our certifications

In hazardous environments where strict safety standards must be met, it is important to use products that are certified and in line with regulations. Discover our certifications:

ATEX

The Directive sets out the requirements and assessment of equipment intended for use in potentially explosive atmospheres.

IECEx

The IECEx system is an international certification system. It is developed by the International Electrotechnical Commission.

SIL

The Safety Integrity Level (SIL) is the ability to reduce the assessed risk by ensuring the reliability of safety systems.