Offshore platforms, used for gas and oil extraction, are extremely high-risk environments. In these isolated and complex facilities, often located hundreds of kilometres from the coast, the presence of flammable, explosive and toxic gases is constant. Even the smallest leak can turn into a disaster. Dozens or hundreds of people work on board, surrounded by high-pressure equipment, volatile hydrocarbons and complex electrical systems. Gas detection on offshore platforms is therefore a fundamental component of prevention and protection strategies.

Offshore platforms: why gas detection is crucial

Without a reliable gas detection system, offshore activities cannot be considered safe or operational. The main advantages of implementation are:

- Prevention of explosions due to combustible gas leaks

- Immediate alert in case of critical thresholds being exceeded

- Protection of personnel, even in closed or ATEX environments

- Compliance with international standards (IECEx, ATEX)

Gas detection also allows remote and centralised monitoring of the status of environments, which is essential in unmanned or partially automated offshore installations.

Offshore platforms: which gases to monitor

In offshore hydrocarbon extraction, processing and transport activities, it is essential to monitor a wide range of hazardous gases, including:

- Methane (CH₄): highly flammable natural gas. It can accumulate in closed or semi-closed areas.

- Hydrogen sulphide (H₂S): extremely toxic, it can be present in deposits. Even small concentrations can be lethal.

- Propane, butane, ethane: liquefied petroleum gases (LPG), highly volatile and flammable.

- Oxygen (O₂): must be monitored to avoid asphyxiating or overly oxygenated atmospheres, which increase the risk of fire.

- Carbon monoxide (CO): produced by combustion, it may be present in engine rooms or generators.

- Volatile organic compounds (VOCs): released by hydrocarbons and solvents used in treatment processes.

A complete offshore gas detection system must cover these gases and ensure maximum accuracy even in extreme environmental conditions.

Gas detection technologies for offshore platforms

The technologies used for gas detection in these environments must be robust, certified and suitable for highly corrosive, humid, windy and salty conditions. The most effective solutions include:

- Infrared (IR) sensors: ideal for methane, propane and CO₂. Resistant to humidity and temperature variations.

- Catalytic sensors: used for flammable gases. Robust and suitable for ATEX zones, but sensitive to the presence of oxygen.

- Electrochemical sensors: perfect for H₂S, CO and oxygen. Guarantee high accuracy and low drift.

- PID (photoionisation detector) sensors: used for VOCs and light hydrocarbon vapours. Reactive and suitable for selective detection.

Sensitron devices are available with ATEX, IECEx and MED certifications and are designed for continuous operation even in severe marine weather conditions.

The importance of gas detection

In addition to protecting personnel, gas detection on offshore platforms is an essential measure for:

- Ensuring uninterrupted operational continuity

- Avoiding plant downtime due to accidents or delayed alarms

- Reducing the environmental impact of undetected leaks

- Improving corporate safety

Discover our produtcs

Sensitron gas detectors are suitable for use in any application:

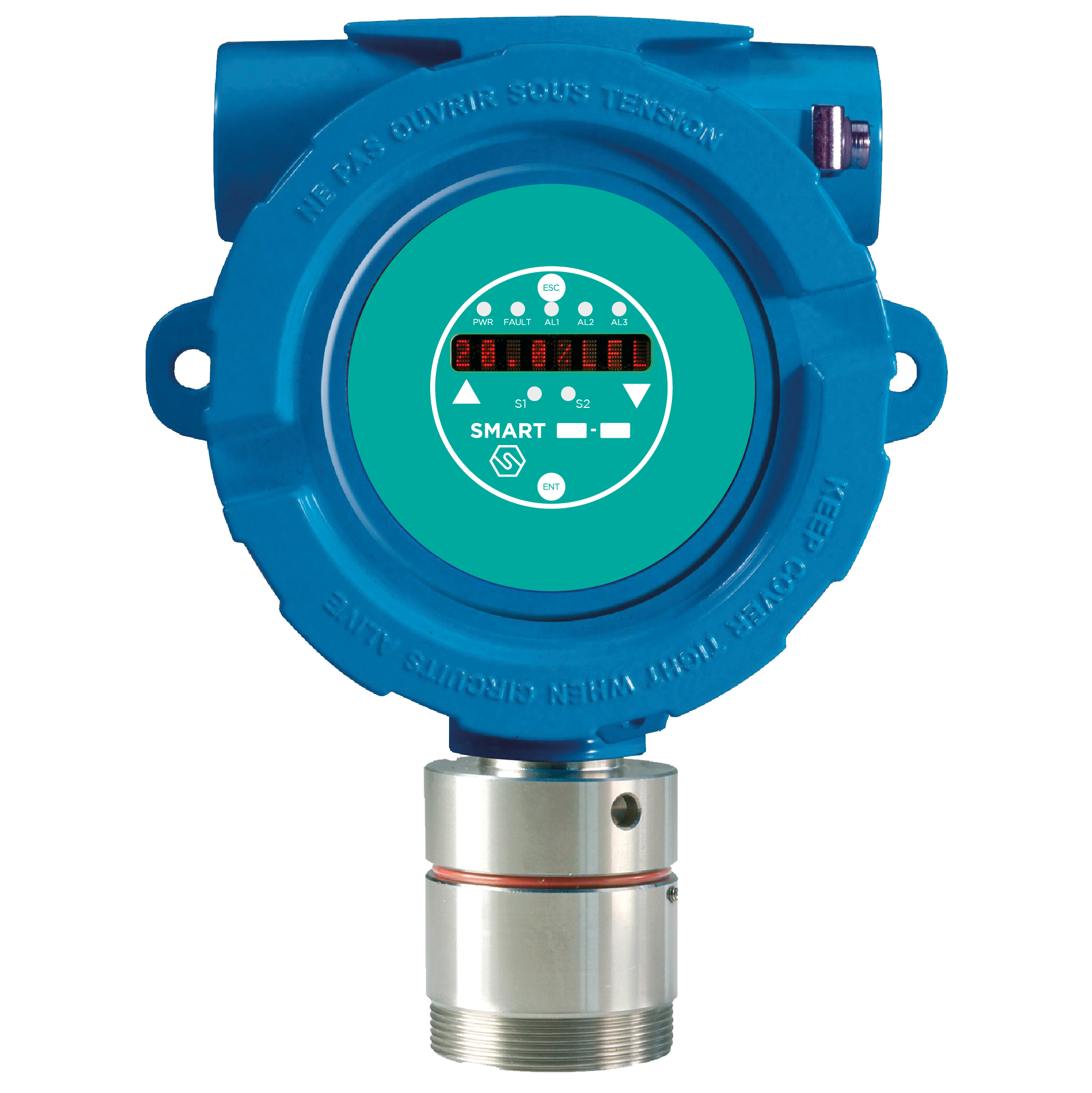

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.ATEX, IECEx and SIL2/3 certified.

SMART S SS

ATEX certified for Zone 1, SIL2 Hardware and SIL3 Software, optional Hart Modem and possibility to have it with stainless steel housing.

SMART S MS

Designed to withstand harsh marine environments, it is SIL 2 Hardware, SIL 3 Software, ATEX Zone 1 certified and has Lloyd's Register certification for marine applications.

Our certifications

In hazardous environments where strict safety standards must be met, it is important to use certified products that comply with regulations. Discover our certifications:

ATEX

The Directive sets out the requirements and assessment of equipment intended for use in potentially explosive atmospheres.

IECEx

The IECEx system is an international certification system. It is developed by the International Electrotechnical Commission.

SIL

The Safety Integrity Level (SIL) is the ability to reduce the assessed risk by ensuring the reliability of safety systems.

Explore in virtual reality

Within the Sensitron metaverse, you can explore application scenarios reconstructed in virtual reality. Find out more about who we are and what we do, walk through a production area and learn more about the dangers associated with gas.