Chemical plants are high-risk environments where the handling of toxic, corrosive, flammable or explosive substances requires extremely rigorous safety standards.

A failure or gas leak can have serious consequences not only for personnel, but also for surrounding communities and the environment. For this reason, safety regulations for chemical plants establish clear criteria for the design, installation and maintenance of prevention systems, including gas detection.

Chemical plants: Why regulations are essential

Regulations are not just a legal obligation: they guarantee that a plant is designed and managed to minimise risks.

For companies, complying with safety regulations in chemical plants means:

- Protecting workers and surrounding communities

- Preventing industrial accidents with environmental and economic impacts

- Ensuring the operational continuity of plants

- Avoiding penalties, plant shutdowns or revocation of authorisations

- Demonstrating responsibility and sustainability to customers and stakeholders

The main reference regulations

Chemical plants must comply with a complex regulatory framework, which includes European regulations, international directives and national provisions. Among the main references are:

- ATEX Directive (2014/34/EU and 99/92/EC): regulates equipment and locations with a risk of explosive atmospheres.

- IEC/EN 60079 standards: international standards for equipment intended for use in potentially explosive atmospheres.

- Legislative Decree 81/08 (Italy): Consolidated Law on Occupational Safety, which incorporates specific requirements for high-risk plants.

Chemical plants: what are the main gases?

The variety of chemical processes involves the presence of various hazardous gases and vapours. The most common ones to detect include:

- Hydrogen (H₂): highly flammable, with a low explosion limit.

- Chlorine (Cl₂): toxic and corrosive, used in various chemical processes.

- Ammonia (NH₃): used in fertilisers and refrigeration, toxic and irritating.

- Hydrogen sulphide (H₂S): extremely toxic, present in refining and chemical processes.

- Solvents and VOCs: flammable and harmful, emitted from production and storage processes.

- Carbon monoxide (CO): by-product of reactions or incomplete combustion.

- Oxygen (O₂): to be monitored for deficient or hyperoxygenated atmospheres.

Technologies for regulatory compliance

To comply with safety regulations in chemical plants, gas detection systems must be certified and suitable for the installation environment. The main technologies include:

- Infrared (IR) sensors: stable and accurate for combustible gases and CO₂.

- Catalytic sensors: for the detection of flammable gases in ATEX atmospheres.

- Electrochemical sensors: ideal for toxic gases such as Cl₂, CO, H₂S, NH₃.

- PID (photoionisation detector) sensors: effective for VOCs and organic solvents.

- The adoption of the appropriate technology ensures not only protection but also full regulatory compliance.

The advantages of a compliant system

Implementing a compliant system offers tangible benefits for chemical plants:

- Reduced risk of serious accidents

- Improved management of production processes in terms of safety

- Enhanced reputation with regulatory bodies and customers

- Business continuity without interruptions due to non-compliance

- Demonstration of commitment to sustainability and social responsibility

Discover our produtcs

Sensitron gas detectors are suitable for use in any application:

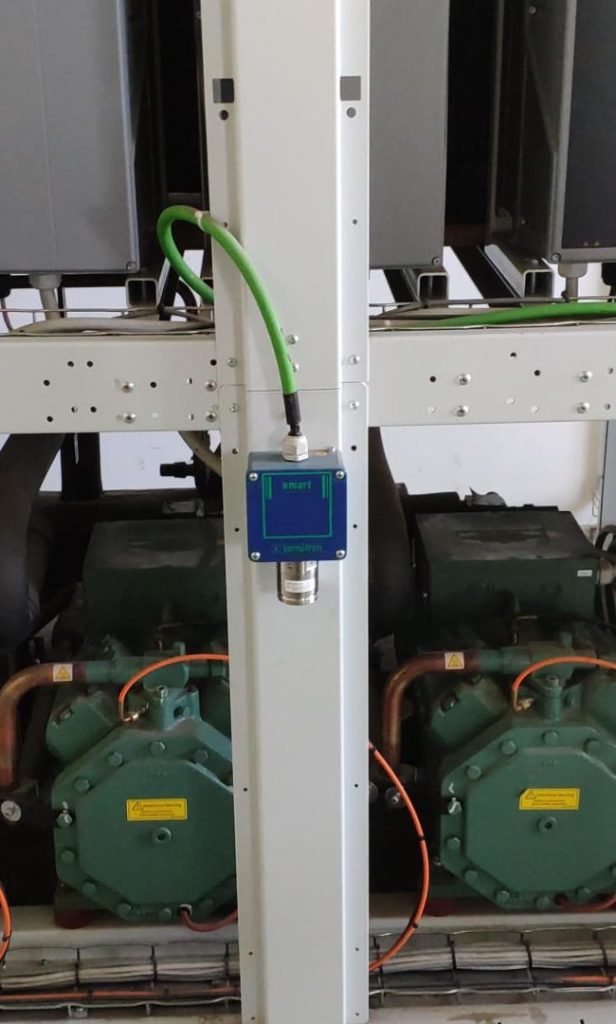

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.ATEX, IECEx and SIL2/3 certified.

SMART 3G D3

Suitable for detecting in classified areas,ATEX, IECEx and SIL2/3 certified, enables non-intrusive field calibration.

MULTISCAN++ S1/S2

Designed to meet the widest market demand for flexibility, they allow the management of up to 264 detectors. ATEX and SIL certified.

Our certifications

In hazardous environments where strict safety standards must be met, it is important to use certified products that comply with regulations. Discover our certifications:

ATEX

The Directive sets out the requirements and assessment of equipment intended for use in potentially explosive atmospheres.

IECEx

The IECEx system is an international certification system. It is developed by the International Electrotechnical Commission.

SIL

The Safety Integrity Level (SIL) is the ability to reduce the assessed risk by ensuring the reliability of safety systems.

Explore in virtual reality

Within the Sensitron metaverse, you can explore application scenarios reconstructed in virtual reality. Find out more about who we are and what we do, walk through a production area and learn more about the dangers associated with gas.