In the industrial world, a breakdown does not just mean machine downtime. It can mean economic losses, personal injury, environmental impact, or regulatory violations. In contexts where flammable, toxic, or asphyxiating gases are handled, a malfunction can have serious consequences. For this reason, scheduled maintenance is a strategic tool for ensuring the safety of industrial plants, improving equipment reliability, and drastically reducing the risk of accidents.

Scheduled maintenance: what is it?

Scheduled maintenance consists of regular and planned checks, calibrations, and replacements, even in the absence of apparent malfunctions. Applied to gas detection systems, this strategy allows you to:

- Ensure consistent sensor performance over time

- Avoid false alarms or missed detections

- Extend the useful life of the equipment

- Maintain compliance with safety regulations (Legislative Decree 81/08, ATEX, ISO)

- Reduce the risk of accidents and unexpected interruptions

Scheduled maintenance is an investment in prevention, not a cost.

Scheduled maintenance: when it is essential

Any plant that uses technical gases or generates potentially hazardous atmospheres must include a scheduled maintenance plan. In particular:

- Chemical and petrochemical plants

- Offshore platforms and refineries

- Warehouses and cold rooms with refrigerants

- Gas storage and distribution stations

- Waste and wastewater treatment plants

- Food and pharmaceutical industries with cryogenic or inert gases

In these contexts, even a single malfunctioning sensor can compromise the effectiveness of the entire safety system.

Planned maintenance: what does it involve?

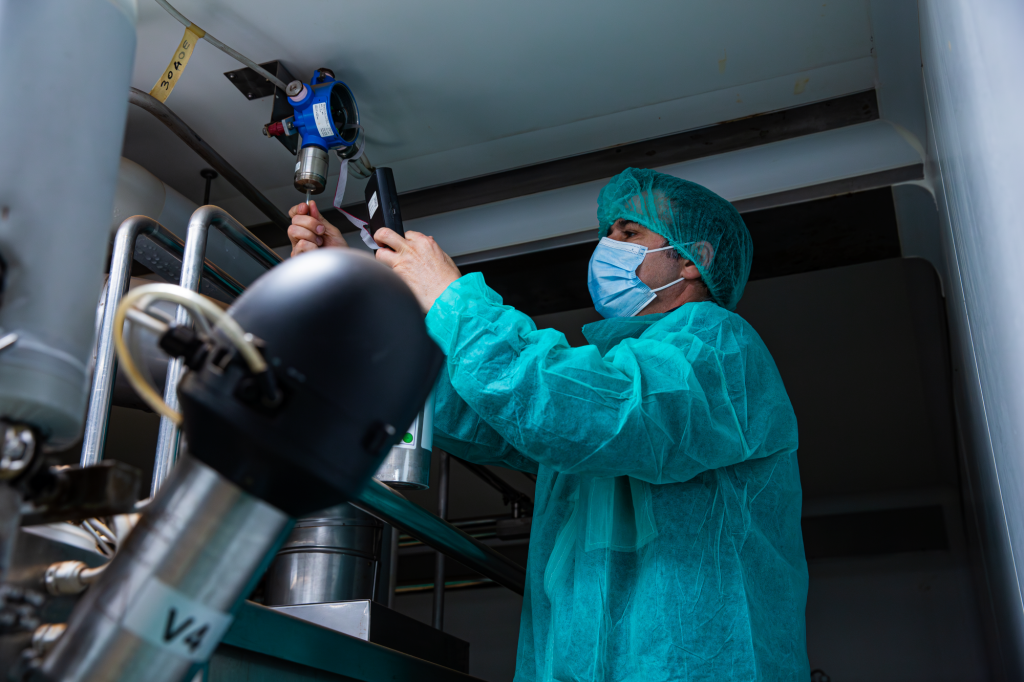

A scheduled maintenance plan for gas detectors involves various technical activities to be performed at regular intervals:

- Checking sensor response with sample gas

- Calibration and recalibration of detectors

- Cleaning and checking hardware

- Functional testing of alarm signals, relays, and digital outputs

- Checking the status of connections and power supply

- Updating the firmware or control software

All these operations must be carried out by qualified personnel and documented in accordance with the manufacturer’s guidelines.

What are the advantages?

Integrating scheduled maintenance into gas detection systems offers numerous concrete benefits:

- Greater device reliability

- Reduced risk of critical failures

- Maintenance of regulatory compliance

- Better management of audits and inspections

- Control of maintenance costs in the medium to long term

- Greater safety for personnel and facilities

Scheduled maintenance creates a controlled environment where emergencies become avoidable events.

Why rely on Sensitron

Sensitron gas detection devices are designed to facilitate every stage of scheduled maintenance, thanks to:

- Self-diagnostic and self-calibration functions

- Intuitive interfaces with intervention alerts

- Integrated event history and maintenance log

We also offer technical assistance services and scheduled maintenance contracts tailored to the actual needs of the system, to guarantee peace of mind and operational continuity.

Discover our produtcs

Sensitron gas detectors are suitable for use in any application:

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.ATEX, IECEx and SIL2/3 certified.

SMART 3G D3

Suitable for detecting in classified areas,ATEX, IECEx and SIL2/3 certified, enables non-intrusive field calibration.

MULTISCAN++ S1/S2

Designed to meet the widest market demand for flexibility, they allow the management of up to 264 detectors. ATEX and SIL certified.

Our certifications

In hazardous environments where strict safety standards must be met, it is important to use certified products that comply with regulations. Discover our certifications:

ATEX

The Directive sets out the requirements and assessment of equipment intended for use in potentially explosive atmospheres.

IECEx

The IECEx system is an international certification system. It is developed by the International Electrotechnical Commission.

SIL

The Safety Integrity Level (SIL) is the ability to reduce the assessed risk by ensuring the reliability of safety systems.

Explore in virtual reality

Within the Sensitron metaverse, you can explore application scenarios reconstructed in virtual reality. Learn more about who we are and what we do, walk through a production area, and discover more details about the dangers associated with gas.